Introduction of pan granulator machine

The pan granulator machine, also known as the disc granulator, is an essential equipment in the fertilizer production industry. Its efficiency and versatility make it a preferred choice for both organic and inorganic fertilizer manufacturing. This guide will delve into the key aspects of the disc pan granulator, including its working principles, benefits, and applications in fertilizer production.

What is a Pan Granulator?

A pan granulator machine is a type of granulation machine used to produce granules from powdery materials. It features a rotating disc that mixes the materials and shapes them into uniform granules through a combination of centrifugal force and gravity. This machine is widely used in the production of various fertilizers, including organic and compound fertilizers.

specifications of pan granulator machine

| Model | Inner diam (mm) | Side height (mm) | Rotation speed ( r/min ) | Motor power ( kw ) | capacity |

| ZL16 | 1600 | 300 | 20 | 3 | 0.4-1(t/h) |

| ZL18 | 1800 | 300 | 18 | 3 | 0.6-1.2(t/h) |

| ZL20 | 2000 | 350 | 16 | 4 | 0.6-2.0(t/h) |

| ZL22 | 2200 | 360 | 15 | 5.5 | 0.8-2.2(t/h) |

| ZL25 | 2500 | 380 | 13.5 | 5.5 | 1-2.5(t/h) |

| ZL28 | 2800 | 400 | 13 | 7.5 | 1-3.0(t/h) |

| ZL30 | 3000 | 420 | 12.5 | 11 | 1-4(t/h) |

| ZL32 | 3200 | 450 | 12.5 | 15 | 1-5.0(t/h) |

| ZL35 | 3500 | 460 | 12 | 18.5 | 1.5-5.5(t/h) |

| ZL36 | 3600 | 460 | 12 | 18.5 | 2-6.0(t/h) |

How Does a Pan Granulator Work?

The pan granulator machine operates on a simple yet effective principle of disc granulation. Here’s an overview of the granulation process:

- Feed Material Preparation

- Powdery materials such as compost, manure, and minerals are prepared and fed into the pan granulation machine.

- Mixing and Granulation

- The rotating disc of the fertilizer pan granulator continuously mixes the materials. As the disc rotates, the materials gradually form granules due to the combined effects of centrifugal force and gravity.

- Granule Formation

- The angle and speed of the disc can be adjusted to control the size and uniformity of the granules. The granules grow layer by layer until they reach the desired size.

- Discharge

- The formed granules are then discharged from the machine and collected for further processing, such as drying or coating, depending on the production requirements.

Advantages of using a pan granulator for fertilizer production

- High Efficiency

- The pan granulator offers high granulation efficiency, producing uniform and spherical granules, which are ideal for fertilizer application.

- Versatility

- This granulation machine is suitable for a wide range of materials, making it versatile for different types of fertilizer production, including organic fertilizer pan granulation.

- Adjustability

- The angle and speed of the rotating disc can be easily adjusted to control granule size, ensuring consistent quality and meeting specific production needs.

- Cost-Effectiveness

- The simple design and low operating costs make the pan granulation machine a cost-effective solution for fertilizer manufacturing.

Applications in Fertilizer Production

Fertilizer pan granulators are especially beneficial in fertilizer production. They are capable of handling a variety of materials, including chemical compounds and organic matter. The organic fertilizer pan granulator variant is specifically designed to cater to eco-friendly fertilizer production processes, which are increasingly preferred for sustainable agriculture practices.

The Granulation Process Explained

The granulation process in a pan granulator equipment involves several key steps to ensure the production of high-quality granules:

- Raw Material Feeding

- Powdery raw materials are fed into the rotating disc.

- Water Addition

- During the granulation process, a controlled amount of water or binder is added to help the powdery materials bind together and form granules.

- Granule Growth

- The rotating disc causes the materials to roll and grow into granules. The angle of the disc can be adjusted to influence the granule size and growth rate.

- Drying and Cooling

- After granulation, the granules are typically dried and cooled to enhance their strength and stability, making them suitable for storage and application.

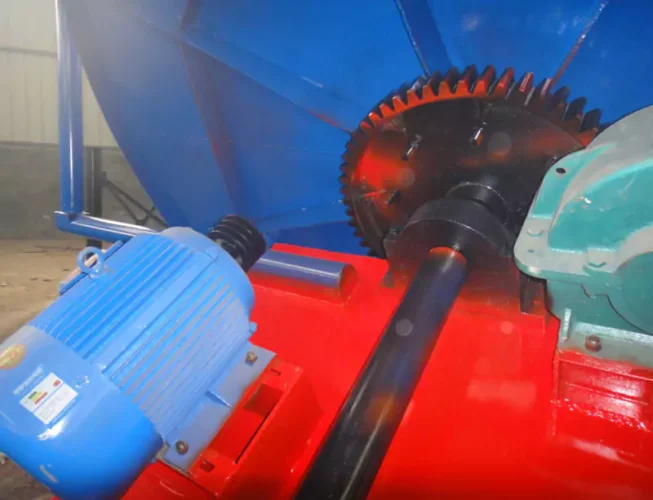

Key Features of a Pan Granulator

- Rotating Disc

- The disc is the central component of the granulator, designed to rotate at variable speeds to control granule formation.

- Adjustable Angle

- The angle of the disc can be adjusted to achieve the desired granule size and uniformity.

- Spray System

- A spray system is often integrated to add water or binders during the granulation process, ensuring proper granule formation.

- Durability

- Made from robust materials, the pan granulator is designed to withstand the rigors of continuous operation in industrial environments.

How to maintain a pan granulator?

- Regular Inspections

- Conduct regular inspections of all components, including the disc, bearings, and drive system, to identify any signs of wear or damage.

- Lubrication

- Ensure all moving parts are adequately lubricated to reduce friction and prevent overheating. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- Cleaning

- Clean the pan granulating machine thoroughly after each production run to prevent material buildup and contamination. Use appropriate cleaning agents and tools to maintain hygiene and efficiency.

- Calibration

- Periodically calibrate the machine to ensure it operates at optimal performance levels. This includes adjusting the disc angle and speed to maintain consistent granule quality.

- Replacement of Worn Parts

- Replace worn or damaged parts promptly to avoid downtime and maintain the efficiency of the granulator. Keep a stock of essential spare parts to ensure quick replacements.

- Safety Checks

- Perform regular safety checks to ensure all protective guards and emergency stops are functioning correctly. This helps in preventing accidents and ensuring the safety of the operators.

Cost of Pan Granulator Machines

The cost of a pan granulator machine can vary widely depending on several factors, including the size, capacity, and additional features of the machine. Here is an overview of the cost considerations:

- Basic Models

- Basic pan granulators without advanced features typically cost between $2,000 and $5,000. These models are suitable for small to medium-scale production.

- Mid-Range Models

- Mid-range pan granulators with additional features such as adjustable angles, integrated spray systems, and enhanced durability range from $5,000 to $15,000. These are ideal for larger operations with higher production demands.

- High-End Models

- High-end pan granulators designed for industrial-scale production can cost upwards of $15,000. These models often come with advanced automation, higher capacity, and superior materials for extended longevity.

- Operational Costs

- In addition to the initial purchase price, consider the operational costs, including maintenance, energy consumption, and spare parts. Investing in a high-quality machine with lower operational costs can be more economical in the long run.

Conclusion

The pan granulator machine is a vital piece of equipment in the fertilizer production industry, offering high efficiency, versatility, and cost-effectiveness. Whether producing organic or compound fertilizers, the pan granulator ensures uniform granule formation, enhancing the quality and consistency of the final product. By understanding its working principles, benefits, applications, maintenance tips, and cost considerations, producers can optimize their fertilizer manufacturing processes, leading to better crop yields and sustainable agricultural practices.