Introduction to Rotary Drum Granulation Technology

rotary drum granulator machines are an important equipment in the fertilizer production industry. Known for its efficiency and versatility, this machine is widely used to produce granulated fertilizers. In this comprehensive guide, we will explore the key aspects of the rotary drum granulator, including its working principles, benefits, and applications in fertilizer manufacturing.

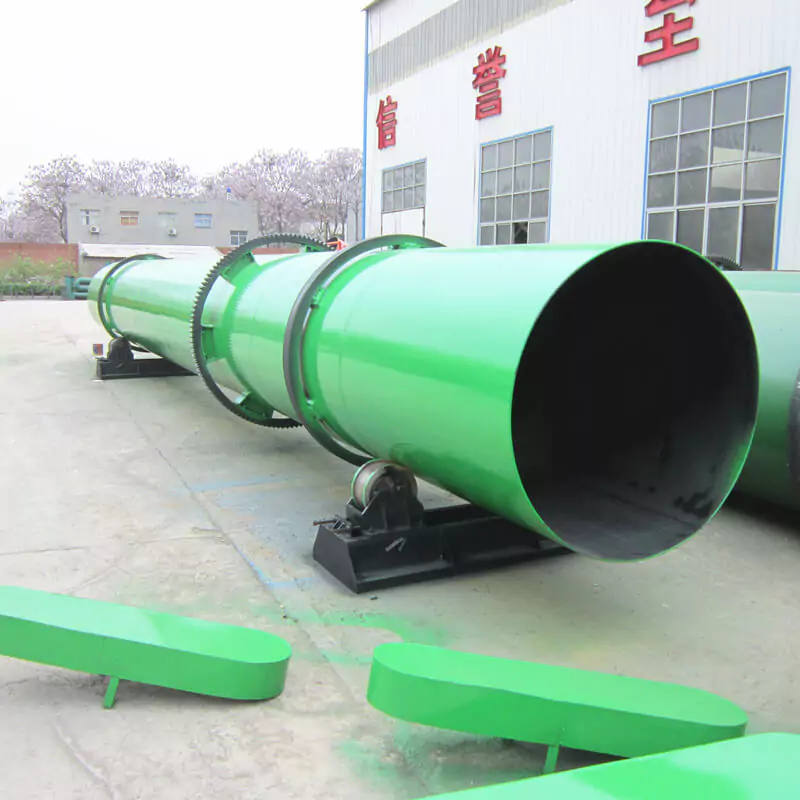

What is a Rotary Drum Granulator Machine?

A Rotary Drum Granulator Machine is an industrial device essential for mass production of granulated fertilizers. It combines physical rolling, chemical reactions, and heat to form uniform, rounded granules from raw, powdery materials. Typically used in the fertilizer industry, this machine facilitates the continuous incorporation of necessary additives, such as binders or moisture, through its long, rotating cylindrical drum. This action helps to compact the materials into distinct pellet forms, making it easier to handle and distribute the fertilizer efficiently.

The robust design of the granulator allows it to handle various materials, making it indispensable for producing both organic and inorganic fertilizers at a high capacity. Its efficiency lies in its ability to produce consistent product quality, optimize material usage, and reduce production costs and environmental impact, making it a preferred choice in modern agricultural practices.

How Rotary Drum Granulator Enhance Fertilizer Production

Rotary drum granulators play a pivotal role in optimizing fertilizer production through several key enhancements:

Efficient Material Processing:

These machines facilitate the continuous and efficient conversion of powdery raw materials into granular form. This is essential for large-scale production, allowing manufacturers to meet substantial agricultural demands effectively.

Enhanced Nutrient Integration:

The rotary drum’s design enables thorough mixing and integration of essential nutrients and binding agents. This process ensures that each granule contains a uniform distribution of all nutrients, improving the effectiveness of the fertilizer.

Heat Utilization:

The process within a rotary drum granulator often involves the application of heat, which helps to cure the fertilizer granules, making them harder and more durable. This heat treatment ensures the pellets are robust enough for handling, storage, and transportation without degradation.

Reduction of Moisture Content:

The granulation process helps to lower the moisture content of the fertilizer product, which is critical for preventing mold growth and caking. This attribute ensures the fertilizer remains dry and free-flowing, facilitating easier application and better soil absorption.

Quality and Compliance:

With the ability to tightly control the granulation environment, these machines help manufacturers adhere to strict quality and environmental standards, producing granules that release nutrients at controlled rates suitable for various soil types and crop needs.

Key Features and Advantages of rotary drum granulator

Enhanced Production Efficiency

The rotary drum granulator’s primary advantage is its capability to produce fertilizers on a large scale efficiently. Its design allows for continuous processing, which is vital for meeting high production demands in modern agriculture.

Consistent Product Quality

The rotary motion ensures that each granule is uniformly coated and rounded, resulting in consistent pellet size and shape. This uniformity is crucial for the precise application of fertilizers, ensuring that nutrients are evenly distributed in the field.

Versatility in Material Handling

Capable of processing a wide array of materials, rotary drum granulators are adaptable to both organic and inorganic fertilizer production. This versatility extends to the ability to incorporate various additives into the granulation process, tailoring the end product to specific agricultural needs.

Cost-effectiveness

With its high capacity and efficient processing, the rotary drum granulator reduces labor and saves time, lowering the overall cost of production. The machine’s durable design minimizes maintenance costs and extends its service life, providing further economic benefits.

Environmental Sustainability

The machine’s enclosed system reduces dust and particulate emissions, which is critical for meeting environmental regulations. Additionally, the efficient use of materials helps in minimizing waste, further enhancing its eco-friendly credentials.

Applications in Modern Fertilizer Manufacturing

Rotary drum granulation equipment is pivotal in modern fertilizer production processes. It supports the efficient transformation of powdery raw materials into granular form, making it easier to distribute and use in agriculture. The process not only optimizes material consumption but also enhances the environmental sustainability of fertilizer production by minimizing dust and runoff.

Cost of Rotary Drum Granulator Machine

The cost of a rotary drum granulator can vary widely depending on several factors, including the size, capacity, and additional features of the machine. Here is an overview of the cost considerations:

Basic Models of ratoary granulator machine

Basic rotary drum granulators without advanced features typically cost between $5,000 and $10,000. These models are suitable for small to medium-scale production.

Mid-Range Models of drum granulator machine

Mid-range rotary drum granulators with additional features such as adjustable angles, integrated spray systems, and enhanced durability range from $10,000 to $30,000. These are ideal for larger operations with higher production demands.

High-End Models of rotary drum granulator

High-end rotary drum granulators designed for industrial-scale production can cost upwards of $30,000. These models often come with advanced automation, higher capacity, and superior materials for extended longevity.

Operational Costs

In addition to the initial purchase price, consider the operational costs, including maintenance, energy consumption, and spare parts. Investing in a high-quality machine with lower operational costs can be more economical in the long run.

What materials can be processed in a rotary drum granulator?

Rotary drum granulators are remarkably versatile in the range of materials they can process, making them indispensable in the fertilizer industry. Here’s a closer look at the types of materials suitable for this equipment:

- Inorganic Fertilizers: Commonly used materials include ammonium nitrate, superphosphate, and potassium sulfate, which are critical components for synthetic fertilizer blends.

- Organic Materials: These granulators are capable of processing various organic substances such as manure, compost, and bio-solids. This adaptability allows for the production of organic fertilizers that are increasingly popular for sustainable farming practices.

- Chemical Powders: The machinery can handle a range of chemical powders that need to be pelletized for ease of application and controlled-release in agricultural settings.

- Minerals: Essential minerals like phosphate rock, gypsum, and lime, which are key for adjusting soil pH levels and enhancing nutrient profiles, can also be granulated in these machines.

The Granulation Process Explained

The granulation process in a rotary drum granulator involves several key steps to ensure the production of high-quality granules:

Raw Material Feeding

Feed powdery raw materials into the rotating drum.

Water Addition

Add a controlled amount of water or binder during the granulation process to help the powdery materials bind together and form granules.

Granule Growth

The rotating drum causes the materials to roll and grow into granules. Adjust the angle of the drum to influence the granule size and growth rate.

Drying and Cooling

Dry and cool the granules after granulation to enhance their strength and stability, making them suitable for storage and application.

How to maintain a rotary drum granulator?

Regular Inspections

Inspect all components regularly, including the drum, bearings, and drive system, to identify any signs of wear or damage.

Lubrication of rotary drum granulator

Lubricate all moving parts adequately to reduce friction and prevent overheating. Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

Cleaning rotary drum granulator machine

Clean the granulator thoroughly after each production run to prevent material buildup and contamination. Use appropriate cleaning agents and tools to maintain hygiene and efficiency.

Calibration of rotary granulator machine

Calibrate the machine periodically to ensure it operates at optimal performance levels. Adjust the drum angle and speed to maintain consistent granule quality.

Replacement of Worn Parts

Replace worn or damaged parts promptly to avoid downtime and maintain the efficiency of the granulator. Keep a stock of essential spare parts to ensure quick replacements.