specification of double roller granulator

Model | FGZL—1 | FGZL—1.5 | FGZL—2 |

Capacity | 0.5—1t/h | 1—1.5t/h | 1.5—2t/h |

granulation rate | ≥85% | ≥85% | ≥85% |

Power | 15kw | 18.5kw | 22kw |

Material moisture content | Max 15% | ||

Gramulation temperature | Constant temperature | ||

pellet | Diameter | 3—15(mm) | |

Strength | 6—20N(resistance to crush force) | ||

Shape | oval |

Note: The finished pellets of this double roller granulator are oval, if you need spherical pellets, you can use the spherical shaper, which is used to make cylindrical and oval pellets (pellets) into spherical pellets. It adopts the working principle of high speed rotation to make spherical pellets.

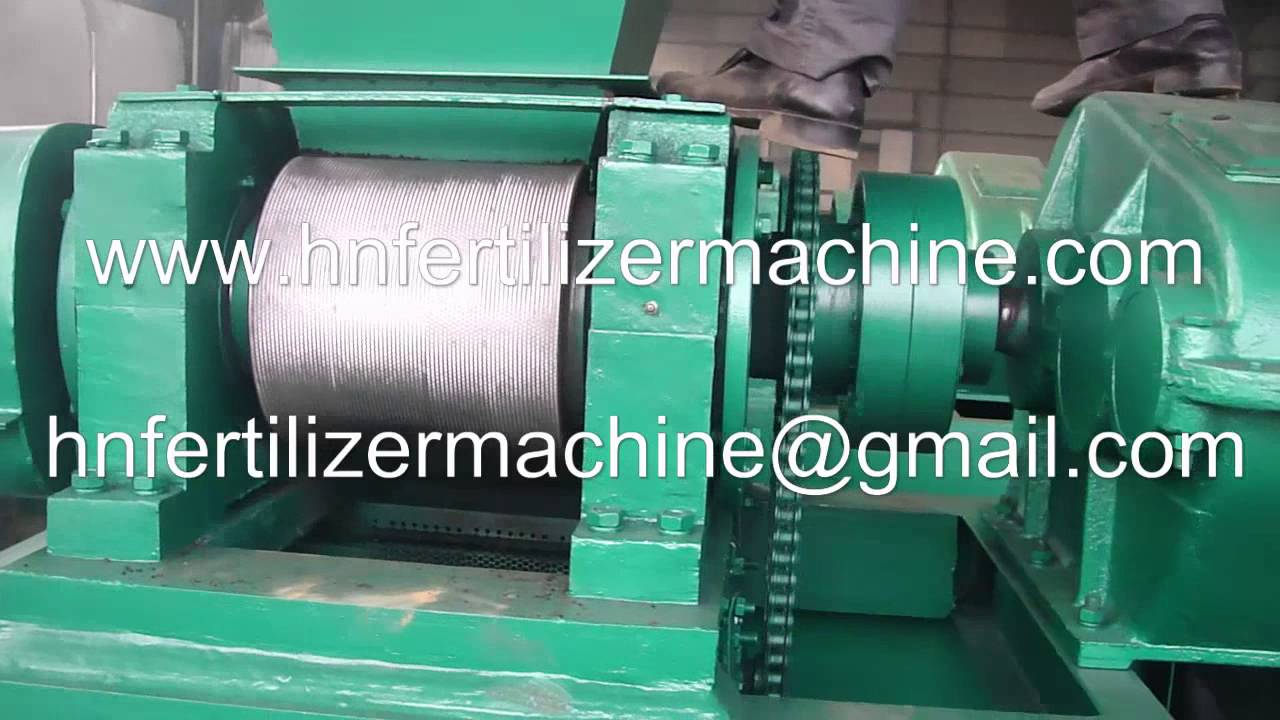

video of double roller press granulator

Double roller granulator is multifunctional fertilizer press machine, this fertilizer roller press granulator can make compound fertilizer and organic fertilizer pellets. It is multifunctional, but the finished granules are oval. It can be made into round pellets by shaper, which is developed by our company. The production process only needs room temperature and no dryer, which can save a lot of energy and cost. The production output of double roller press granulator is 0.5-1t/h, 1-1.5t/h and 1.5-2t/h respectively. If you want to use the disc granulator, it is also the best organic fertilizer machine. we have rotary drum granulator to make compound fertilizer as your another choice.

Advantages of roller press granulator

1.The roller press granulator has less investment and good economic benefit.

2. Compact structure, scientific and reasonable, advanced technology of complete set of fertilizer extrusion granulator.

3. No three waste emissions, stable operation and convenient maintenance.

4. This double roller granulator can directly extrude dry powder material into granules, which belongs to the dry granulation method.

Application of double roller granulator

The roller extrusion granulator is widely adaptable, the raw materials are diammonium phosphate, calcium superphosphate, gypsum, sheep manure, cow manure, chicken manure, pig manure, bentonite and other livestock manure waste, etc. The double roller granulator has high productivity.

This fertilizer double roller granulator machine can produce all kinds of high concentration organic fertilizer, inorganic fertilizer, compound fertilizer and other kinds of fertilizers, especially rare earth fertilizer, potash fertilizer, ammonium bicarbonate series. Domestic leading, this double roller granulator machine whole fertilizer production line use without rotary dryer machine.

Working principle

The double roller granulator represents an fertilizer extrusion granulator. The dry material is compressed into hard and dense blocks under pressure, which is the extrusion process. The block material is crushed, screened and granulated, which is the granulation process. The effect of extrusion is to squeeze out the air between the particles so that the particles are close enough together to create an interaction force. The particle hardness of crushed pelletized particles is mainly due to the mutual attraction between molecules.

Our double-roller press pelletizer is a positive displacement continuous extrusion pelletizer. This double-roller press granulator has two main working parts.

1.Pressing and squeezing section: the material is pressed into large and dense hard cakes under pressing pressure.

2. Granulating section: The filter cake is crushed and sieved into small particles.